Innovation Alphabet

Industry 4.0

In a nutshell

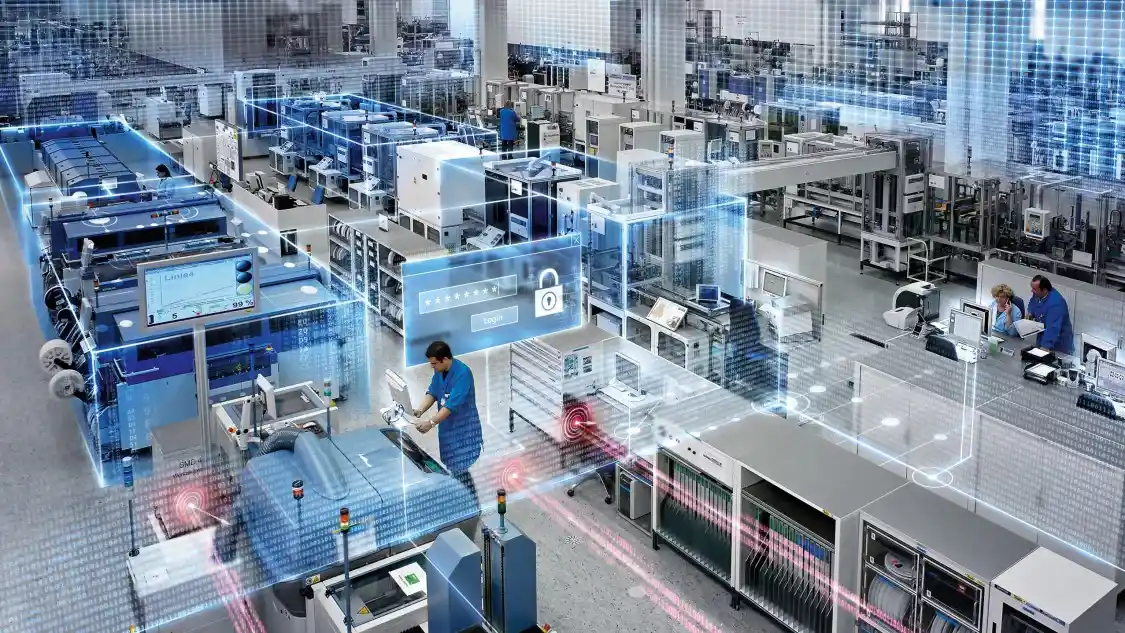

Charlie Chaplin’s “Modern Times” has never been far away. The real modernity is Industry 4.0: the result of the fourth industrial revolution, which has transformed supply chain automation, monitoring, and analysis processes through smart technology. Smart factories arise in response to a need for growth and innovation; they are networked, data-driven, and AI-based.

Application Fields

• Industry: Industry 4.0 surrounds itself with interconnected machines that talk to each other to perform self-diagnostics and predictive maintenance. Thanks to IIoT (Industrial Internet of Things), factories can autonomously predict the risk of production failure, take the best preventive measures and self-repair. The smart factory enables customization of production according to the customer, quickly designs and modifies products. And also avoids downtime. Robots work in contact with humans and learn from them. the workflow can be reproduced and analyzed virtually, so as to verify its operation and enhance its performance.

• Automotive Industry: The fourth industrial revolution has also landed in the world of automotive dealerships. And it is offering benefits such as excellence in data and information management, collaborative capability of the sales organization, and product lifecycle innovation with a view to the circular economy.

• Food Industry: One of the areas of the food sector particularly involved in the smart revolution concerns the recall of batches that are damaged or subject to consumer complaints. Industry 4.0 can support the food sector in the new habits of consumers. Nowadays, they are very concerned about product quality. In this regard, smart labeling – a combination of wireless technology, software applications and cloud platforms – enables consumers to verify the authenticity of the product by scanning its label and obtaining evaluations, reviews, videos and other loyalty opportunities.

Do you have a Strategy & Innovation challenge to tackle? Let’s face it. Together.

C-levels from these companies (AND MORE) relied on my expertise to overcome thEIR CHALLENGES IN THIS AREA. And You can, too.

Can I help you?Industries

• Industry 4.0 in the production industry

PMS 4.0 is an application that guides every routine operation by transferring all control and reaction activities into a shared digital environment. It is accessible by operators via tablets and smartphones located in production departments. PMS is designed to control and manage repetitive issues such as shift succession, observance of HSE safety standards, workstation compliance, time and mode, and man-machine alignment.

• Industry 4.0 in the automotive industry

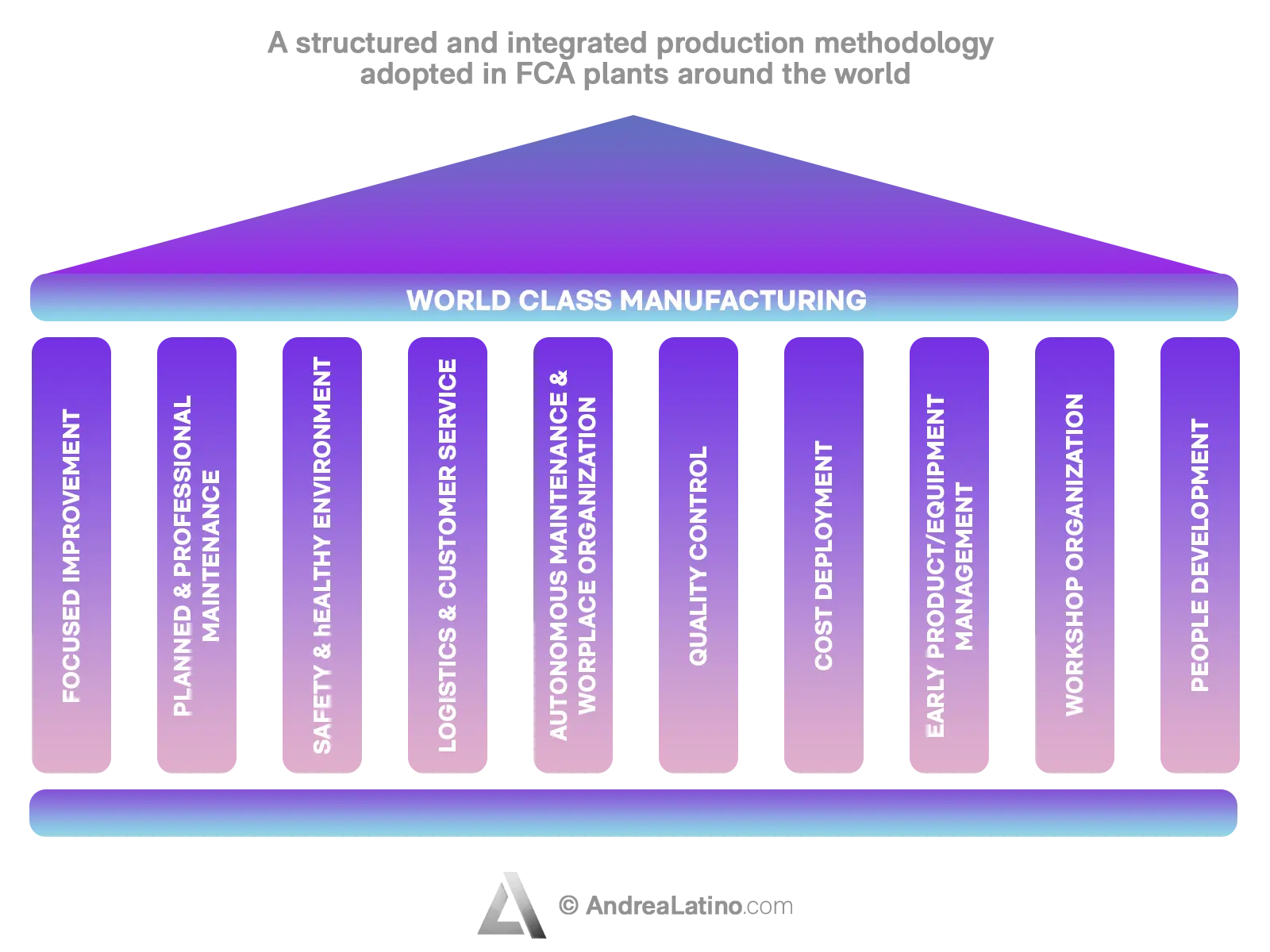

World Class Manufacturing (WCM) is a structured and integrated production methodology adopted in FCA plants around the world. It involves the entire organization: safety, environment, maintenance, logistics and quality. The main objective of WCM is the continuous improvement in all areas of production in order to ensure the quality of the final product and meet customer expectations. Projects developed under the WCM method – based on a high level of employee engagement – aim to eliminate all forms of waste and loss until zero accidents, zero waste, zero breakdowns, and zero inventory are achieved.

• Industry 4.0 in the mechanical industry

The F.lli Carminati mechanical workshop decided to become part of Industry 4.0 by trying to interconnect the broaching loading robot with the company’s management system and MES (Manufacturing Execution System). The aim was to automate data collection, track downtime and know the cost related to each job order. To meet this need, the company relied on iDaq software (typical of smart factories), which is used to communicate directly with the robot and collect key production and process data, such as the status of the robot or the number of parts produced.

Business Functions

• Industry 4.0 in support of customer experience

The LVMH (Louis Vuitton Moët Hennessy) group has signed a partnership with Google Cloud. Why? To create a personalized customer experience by accelerating innovation and developing cloud-based Artificial Intelligence solutions. The new AI and machine learning technologies improve business operations because they contribute to demand forecasting and warehouse logistics. They also enrich the customer experience with personalized services tailored to the customer.

• Industry 4.0 in support of internal process transformation

The Solari company in Udine opted for a 360-degree IT conversion involving products and internal work processes. Those were made more efficient through the use of technology. Product Lifecycle Management (PLM), for example, is a software that fully manages the lifecycle of a product, from its creation to its disposal.

Stay in wonderland

Let me show you how deep the rabbit hole goes.

Check out more of the Innovation Alphabet:

3D Printing

3D Printing

“3D printing” is a process carried out by an electronic device which, instead of resorting to the canonical ink, it molds almost any kind of material: from concrete to living tissue, most usually plastic, but also metal. And the operating principle is similar to that of a traditional printer. The creation of three-dimensional models can lead to the redesign of a company’s production capabilities.

Dive In

5G

5G

5G is the new frontier of cellular telephony. It was designed to improve (or completely replace) previous generations of mobile networks. The 5th generation features lower latency, ensuring flawless performance of business applications and many other digital experiences – thus enabling the new cultural generations to furiously play Fortnite away from home.

Dive In

Advanced Analytics

Advanced Analytics

The term “Advanced Analytics” refers to the ability to autonomously or semi-autonomously analyze data and content to identify correlations, develop analyses, predictions, and recommendations. It is not just a matter of collecting information and then organizing it into watertight compartments: the ultimate goal is to identify a dialogue pattern from a data-driven perspective.

Dive In

Agile

Agile

Agile is an approach to software development designed to respond to change. Teams quickly analyze the context in which they operate, identify uncertainties faced, and figure out how to adapt to always move forward. Interaction between individuals comes before processes and tools; collaboration with the customer is more important than negotiating contracts.

Dive In

Ansoff Matrix

Ansoff Matrix

The Ansoff Matrix is a marketing planning model that arises from the intersection of new and existing products and markets. It derives four possible strategies for expanding the company’s market, which are built around four variables with a changeable factor of risks and possibilities: existing product, new product, existing market, new market.

Dive In

Artificial Intelligence

Artificial Intelligence

Artificial Intelligence is not strictly defined. Basically, it is a computer system able to make decisions in an independent and flexible way. A good AI application can perform everyday tasks better than an average person (e.g., identifying other people from their photos on social media or beating the best chess player). Nothing to fear, then. Unless you are a chess champion.

Dive In

Artificial Scarcity

Artificial Scarcity

We often tend to desire what we cannot have. Or what we are in danger of losing: Artificial Scarcity is a strategy that flaunts a limited number of items that do not correspond to actual availability. The goal is to stimulate the perception in consumers that the stock of items is about to run out and thus create a need based on the “fear of being cut off” or the intention to buy the item in order to resell it at a higher price.

Dive In

Attack Surface

Attack Surface

The term attack surface refers to the part of a system that may be subject to attack or breach by hackers. The smaller that surface is, the easier it will be to protect it. Indeed, the Internet is an ocean of deep, dark waters: those who navigate it must be aware that they are exposing themselves to a flood of digital risks. Yet, ironically, we do not need a big boat to shelter us.

Dive In

Augmented Reality

Augmented Reality

Augmented Reality is an ever-evolving technology that overlays multimedia information on top of our common sensory horizon to gain a deeper understanding of our surroundings. No, it doesn’t allow you to step out of the Matrix dream simulation, nor can it be accessed by swallowing a red pill. But neither is it the disturbing experience of the Playtest episode of Black Mirror.

Dive In

Balanced Scorecard

Balanced Scorecard

In business, as in life, you need balance. The Balanced Scorecard is a holistic tool for strategic management. It offers, in fact, the possibility of assessing corporate performance in its wholeness. An overview that embraces four perspectives: the business/financial side, customers and stakeholders, internal processes, and learning and growth.

Dive In